UPSTREAM SPECIALITY CHEMICALS

Asphaltene precipitation poses a significant challenge in the crude oil industry, leading to flow assurance issues such as plugs and deposits in critical components of the system. Revive Energy Chemicals offers specialized Asphaltene Inhibitors designed to mitigate these challenges and ensure efficient operations.

Flow Assurance Challenges:

Asphaltene precipitation can result in blockages and deposits in formations, tubing, separators, and other vital parts of the oil production and processing system. These issues not only hamper flow efficiency but also increase operational downtime and maintenance costs.

Revive Energy Chemicals – Specialist Expertise and Treatments:

Revive Energy Chemicals brings decades of expertise in the Oil & Gas industry to address asphaltene-related flow assurance challenges effectively. Our specialized treatments are meticulously formulated to interfere with the precipitation and flocculation of asphaltene aggregates, preventing their deposition across the system.

Revive Energy Chemicals – Application Methods:

Our Asphaltene Inhibitors can be applied through squeeze applications or continuous injection upstream of the asphaltene onset pressure. This flexibility allows for tailored solutions based on the specific characteristics of the crude oil and the operational requirements of the system.

Revive Energy Chemicals’ solutions are designed to address these complexities, optimizing water quality and separation efficiency.

By leveraging our expertise and innovative treatments, Revive Energy Chemicals offers comprehensive solutions to control asphaltene precipitation and deposition in crude oil systems. Our Asphaltene Inhibitors not only mitigate flow assurance challenges but also contribute to improved operational efficiency and system reliability. Contact us to discover how we can tailor the correct solution for your asphaltene-related separation and water quality issues.

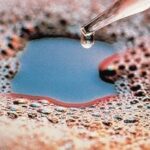

Corrosion poses a significant threat to the integrity and reliability of oil and gas production systems. Revive Energy Chemicals offers a comprehensive range of corrosion inhibitors tailored to mitigate the risk of corrosion caused by various factors such as CO2, H2S, organic acids, and more.

First Line of Defense

Corrosion inhibitors serve as the primary line of defense against corrosion in oil and gas fields and production systems. They address localized, under deposit, galvanic, and other forms of corrosion that can lead to pipeline and equipment failure, ensuring operational safety and longevity.

Revive Energy Chemicals – Extensive Range of Inhibitors

Revive Energy Chemicals provides a full spectrum of inhibitors designed to prevent all types of corrosion encountered in the oil and gas industry. Our portfolio includes products specifically formulated for different applications, including deepwater basins and environmentally sensitive regions, where many oil and gas fields are located.

Revive Energy Chemicals – Tailored Solutions

With extensive corrosion inhibitor development and testing capabilities, we excel in designing test programs that replicate your field environment and recommend appropriate mitigation strategies. Our solutions are customized to suit the unique requirements of each client and application, ensuring optimal performance and cost-effectiveness.

Revive Energy Chemicals – Diverse Applications

Our portfolio encompasses corrosion inhibitors for various applications, including oxygen corrosion in closed-loop systems, top-of-line corrosion (TLC), encapsulated treatments for downhole use, batch corrosion inhibitors, and multifunctional products. We also offer corrosion inhibitors for midstream and downstream applications.

Revive Energy Chemicals is committed to delivering cutting-edge corrosion prevention solutions that empower oil and gas operators to safeguard their assets and optimize operational performance. Our unwavering dedication to innovation, coupled with our extensive expertise and diverse product portfolio, positions us as a trusted partner in corrosion mitigation across the entire oil and gas value chain. Contact us today to explore how our corrosion inhibitors can enhance the integrity and longevity of your production systems. corrosion risks, enhance operational safety, and optimize asset performance. Contact us to discover how our corrosion prevention solutions can benefit your operations.

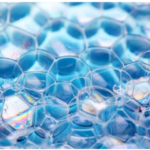

Revive Energy Chemicals offers advanced foam control solutions designed to optimize gas and oil production while minimizing operational costs and complexities. Our innovative range of foamers and defoamers provide comprehensive benefits tailored to meet the diverse needs of the energy industry.

Foamers: Liquid and Solid Options

Our foamers are engineered to effectively unload liquids from gas and oil wells, enhancing gas production and reducing the frequency of shut-ins. Key benefits include:

- Maximized Production: Tailored treatment programs designed to optimize well performance and increase gas output.

- Cost Efficiency: Our foamers can be combined with other treatment chemistries, such as corrosion and scale inhibitors, reducing the need for multiple injection points and lowering overall treatment costs.

- Flexible Application: Available for continuous or batch treatment, our foamers can be deployed using liquid formulations or solid sticks, keeping capital investment low.

Defoamers: Efficient Liquid Carryover Control

To address the challenges of liquid carryover in separators and other processing units caused by foaming, Revive Energy Chemicals offers targeted defoaming solutions. Our defoamers provide several critical advantages:

- Boosted Production Targets: By limiting the likelihood of process upsets, our defoamers help achieve and maintain higher production targets.

- Optimized Operations: Fine-tuning defoamer dosage and application helps optimize process efficiency, preventing costly issues such as filter plugging and asphaltene deposition.

Revive Energy Chemicals is committed to delivering high-performance foam control products that not only improve operational efficiency but also contribute to significant cost savings. Our tailored solutions ensure that your production processes remain smooth and efficient, allowing you to focus on maximizing output and profitability.

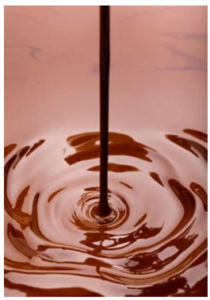

Paraffin management is an essential component of effective flow assurance in the oil and gas industry. Revive Energy Chemicals provides advanced paraffin inhibitors designed to prevent and remediate paraffin deposits, ensuring smooth operations and enhanced profitability.

Revive Energy Chemicals – Innovative Paraffin Inhibitors

Our paraffin inhibitors utilize a proprietary blend of hydrocarbons to effectively liquify paraffin buildup in flow lines, storage tanks, and crude oil pipelines. These inhibitors form a molecular bond with crude oil, eliminating the need for separation before refining. Key benefits include:

- Improved Pumpability: By lowering the pour point of treated crude, our inhibitors enhance the pumpability and flow characteristics of crude oil.

- Increased Production Efficiency: Preventing paraffin deposition reduces the need for pigging and cleaning, minimizing maintenance costs and downtime.

Revive Energy Chemicals – Tailored Chemistries for Optimal Performance

Revive Energy Chemicals offers a range of specialized chemistries to address various aspects of paraffin management:

- Pour Point Depressants (PPDs): Our PPDs limit paraffin crystal growth, maintaining low product viscosities and high production rates.

- Solvents and Dispersants: Designed to dissolve existing paraffin deposits in tubing, flowlines, and service equipment, these products boost production rates and lower pumping costs.

Revive Energy Chemicals – Operational and Economic Benefits

By integrating Revive Energy Chemicals’ paraffin inhibitors into your production systems, you can achieve significant operational and economic benefits:

- Enhanced Flow Assurance: Effective paraffin management ensures continuous and efficient flow of crude oil, reducing the risk of blockages and flow interruptions.

- Cost Savings: Lower maintenance and operational costs through reduced pigging and cleaning frequency, as well as decreased energy expenditure for pumping.

Revive Energy Chemicals is dedicated to providing cutting-edge solutions that enhance the efficiency and profitability of your operations. Our paraffin inhibitors not only prevent and remediate paraffin deposits but also improve the overall flow assurance, ensuring that your production systems run smoothly and cost-effectively.

Effective scale management is crucial in the production environment, where hard deposits of inorganic minerals can severely reduce production efficiency and significantly increase operating costs. With the increasing complexity and depth of both onshore and offshore operations, managing scale has become more challenging than ever. Revive Energy Chemicals offers advanced scale management solutions designed to address these challenges and ensure smooth, cost-effective operations.

Revive Energy Chemicals – Continuous Improvement Strategy

Our approach to scale management centers around a continuous improvement strategy that leverages industry-leading products and expertise in prediction, analysis, and monitoring. Key aspects of our strategy include:

- Risk Minimization: By employing advanced scale inhibitor chemistries, we reduce the risk of scale formation and associated production downtimes.

- Optimized Intervention Costs: Our solutions are designed to optimize intervention costs, ensuring that scale management efforts are both effective and economically viable.

Revive Energy Chemicals – Technology and Expertise

Revive Energy Chemicals combines state-of-the-art technology with extensive industry expertise to deliver comprehensive scale management solutions. Our approach includes:

- Prediction: Advanced modeling and simulation tools to predict scale formation and develop proactive management plans.

- Analysis: Rigorous analysis of production systems to identify potential scale issues and tailor inhibitor chemistries accordingly.

- Monitoring: Continuous monitoring of production environments to ensure the effectiveness of scale management strategies and make adjustments as needed.

Operational and Economic Benefits with Revive Energy Chemical Products

Implementing Revive Energy Chemicals’ scale management solutions offers significant operational and economic benefits:

- Enhanced Production Efficiency: By preventing scale formation, our solutions ensure that production systems operate at optimal efficiency.

- Reduced Operating Costs: Minimizing scale-related issues leads to lower maintenance and intervention costs, reducing overall operating expenses.

Revive Energy Chemicals is committed to providing innovative and effective scale management solutions that enhance the efficiency and profitability of your operations. Our advanced chemistries and expert services ensure that your production systems remain free from scale-related disruptions, allowing you to focus on maximizing output and minimizing costs.

Revive Energy Chemicals offers comprehensive microbial management services designed to mitigate operational risks and ensure the integrity of production systems. By leveraging customized biocide solutions and advanced monitoring services, we effectively control microbial-influenced corrosion (MIC) and address various challenges posed by bacterial activity in oil and gas operations.

Revive Energy Chemicals – Customized Biocide Solutions

Our microbial management services are built around the use of tailored biocide solutions that specifically target microbial activity in production systems. Key benefits include:

- Risk Minimization: Our biocides minimize the risks of souring and plugging in reservoirs and production systems, ensuring smoother and more reliable operations.

- Increased Production Uptime: By preventing microbial growth that can cause slowdowns or shutdowns, we help maintain high production rates and system uptime.

Revive Energy Chemicals – Monitoring Services

In addition to biocide application, we offer advanced monitoring services to track and manage microbial activity. This ensures that any potential issues are identified and addressed promptly, maintaining the efficiency and safety of your operations.

Key Features and Benefits with Revive Energy Chemicals

Revive Energy Chemicals’ microbial management solutions provide several critical advantages:

- Wellbore and Production System Maintenance: Our solutions keep wellbores and production systems free from plugging or production rate slowdowns, enhancing overall operational efficiency.

- Operational Risk Reduction: By preventing injector plugging and controlling aggressive MIC, we reduce the risk of equipment failure and extend the lifespan of production equipment.

- Environmental Protection: Effective microbial management helps avoid severe environmental consequences that can result from uncontrolled bacterial growth and corrosion failures.

Operational Integrity and Efficiency with Revive Energy Chemicals

Our microbial management approach ensures the integrity of your production systems by addressing the root causes of MIC and other bacterial challenges. This holistic approach combines:

- Customized Solutions: Tailored biocide formulations that effectively target the specific microbial threats in your systems.

- Advanced Monitoring: Continuous surveillance and analysis to detect and mitigate microbial activity before it leads to significant problems.

Revive Energy Chemicals – Commitment to Excellence

Revive Energy Chemicals is dedicated to providing industry-leading microbial management solutions that enhance the efficiency, safety, and profitability of your operations. Our advanced biocide chemistries and monitoring services are designed to keep your production systems running smoothly, minimizing downtime and operational risks while protecting the environment.

With Revive Energy Chemicals’ microbial management services, you can be confident in maintaining optimal production performance and safeguarding the integrity of your assets against microbial threats.

Revive Energy Chemicals offers a range of cost-effective demulsifiers designed to enhance fluid separation in oil and gas production systems. Our emulsion breakers are formulated to meet specific application or facility requirements, ensuring efficient removal of water from oil and oil from water. This targeted approach not only improves overall production efficiency but also eliminates the need for separate water clarifier applications, thereby streamlining operations and reducing costs.

Revive Energy Chemicals – Customized Demulsifier Solutions

Our demulsifiers are tailored for various production environments, providing highly effective solutions for fluid separation. Key features include:

- Wide Range of Intermediates and Finished Products: We offer a diverse portfolio of demulsifiers that can be customized for specific applications, ensuring optimal performance across different production scenarios.

- Efficient Water and Oil Separation: Our products excel at removing water from oil and oil from water, enhancing the quality of both the produced oil and disposal water.

Revive Energy Chemicals – Versatility Across Crude Types and Well Conditions

Revive Energy Chemicals’ emulsion breakers are suitable for a wide range of crude types and well conditions, including:

- Light, Medium, and Heavy Crudes: Our demulsifiers are effective across various crude oil grades, ensuring consistent performance regardless of oil density.

- Conventional and Enhanced Oil Recovery (EOR) Wells: Whether for conventional production or EOR processes, our solutions improve fluid separation efficiency.

- Unconventional Wells: Tailored to meet the unique challenges of unconventional wells, our emulsion breakers ensure reliable performance in these demanding environments.

Operational and Economic Benefits with Revive Energy Chemicals

Implementing Revive Energy Chemicals’ emulsion breakers offers several significant advantages:

- Improved Oil Recovery: By efficiently separating water from oil, our demulsifiers enhance oil recovery rates, maximizing production output.

- Reduced Treatment Costs: Eliminating the need for separate water clarifier applications simplifies the treatment process, reducing operational expenses.

- Enhanced Disposal Water Quality: Effective oil removal from disposal water ensures compliance with environmental regulations and reduces the environmental impact of production activities.

Revive Energy Chemicals – Commitment to Excellence

Revive Energy Chemicals is committed to providing high-performance emulsion breakers that enhance the efficiency and profitability of your production systems. Our solutions are developed with a deep understanding of the unique challenges faced in oil and gas operations, ensuring that our products deliver reliable and cost-effective results.

By choosing Revive Energy Chemicals’ emulsion breakers, you can optimize fluid separation processes, improve production efficiency, and achieve significant cost savings. Our tailored solutions ensure that your operations run smoothly and efficiently, allowing you to focus on maximizing output and profitability.

Revive Energy Chemicals offers advanced water clarifiers designed to effectively remove oil and other insoluble matter from water in production systems. Our water clarifiers are tailored to lower operational costs and minimize facility disruptions, providing efficient and reliable solutions for various separation needs.

Revive Energy Chemicals – Customized Solutions for Cost-Effective Treatment

Our water clarifiers are formulated to meet the specific requirements of each application, ensuring optimal performance and cost-efficiency. Key features include:

- Effective Removal of Contaminants: Our clarifiers efficiently remove oil and other insoluble matter, enhancing water quality and ensuring compliance with environmental standards.

- Cost Reduction: By providing tailored solutions, we help lower treatment costs and minimize the impact on facility operations.

Revive Energy Chemicals – Onsite Evaluation and Optimization

Revive Energy Chemicals takes a comprehensive approach to water clarification by offering onsite evaluation services. Our experts assess the performance of our clarifiers in your specific separation equipment, ensuring the best possible treatment solution. This includes:

- Customized Product Formulation: Based on onsite evaluations, we formulate products that address the unique challenges of your separation process.

- Optimal Treatment Solutions: Our tailored approach ensures that the clarifiers provide the most effective treatment, improving operational efficiency and reducing downtime.

Revive Energy Chemicals – Versatility and Reliability

Our water clarifiers are versatile and can be used in various types of separation equipment, making them suitable for a wide range of applications. Benefits include:

- Enhanced Separation Efficiency: By optimizing the removal of oil and insoluble matter, our clarifiers improve the overall efficiency of separation processes.

- Minimal Facility Disruption: Our products are designed to integrate seamlessly into existing systems, reducing the need for extensive modifications or interruptions to operations.

Revive Energy Chemicals – Commitment to Operational Excellence

Revive Energy Chemicals is dedicated to delivering high-quality water clarifiers that enhance the efficiency and reliability of your production systems. Our commitment to excellence ensures that our solutions are not only effective but also tailored to meet the specific needs of each client.

By choosing Revive Energy Chemicals’ water clarifiers, you can achieve superior water quality, reduce operational costs, and maintain smooth, efficient facility operations. Our expertise and customized approach ensure that you receive the best possible treatment solutions for your separation needs.

Our portfolio includes both triazene and non-triazene H2S scavengers, providing a versatile and effective means of managing hydrogen sulfide in various production environments. Key features and benefits include:

- Corrosion Risk Reduction: By effectively removing H2S from production streams, our scavengers significantly reduce the risk of corrosion in equipment and pipelines, extending the lifespan of your assets.

- Enhanced Safety: Managing H2S levels helps mitigate HSE hazards, protecting personnel and the environment from the harmful effects of hydrogen sulfide exposure.

Revive Energy Chemicals – Comprehensive Product Portfolio

Revive Energy Chemicals offers a diverse range of H2S scavengers to meet the specific needs of different production scenarios:

- Triazene Products: Our triazene-based scavengers are highly effective in neutralizing H2S, providing robust protection against corrosion and sour gas-related hazards.

- Non-Triazene Products: For applications where triazene-based solutions are not suitable, we offer non-triazene alternatives that deliver comparable performance and safety benefits.

Revive Energy Chemicals – Tailored Solutions for Optimal Performance

Our approach to H2S management involves a thorough assessment of your production system to identify the most suitable scavenger solution. Benefits of our tailored approach include:

- Customized Formulations: We develop specific formulations that address the unique challenges of your production environment, ensuring optimal H2S removal and system protection.

- Operational Efficiency: By selecting the appropriate scavenger type and formulation, we help improve the efficiency of your production processes, minimizing downtime and maintenance costs.

Revive Energy Chemicals – Commitment to Safety and Environmental Protection

Revive Energy Chemicals is dedicated to providing high-performance H2S scavengers that prioritize safety and environmental stewardship. Our solutions are designed to meet stringent regulatory standards, ensuring that your operations remain compliant and environmentally responsible.

By choosing Revive Energy Chemicals’ H2S scavengers, you can confidently manage sour production streams, reduce corrosion risks, and enhance the safety and efficiency of your operations. Our expertise and comprehensive product offerings ensure that you receive the most effective and reliable H2S management solutions available.

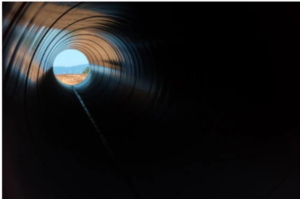

Revive Energy Chemicals Drag Reducing Agents (DRAs), also known as flow Enhancers / improvers, are chemicals used in the oil and gas industry to reduce frictional pressure loss in pipelines, thereby increasing the flow capacity and efficiency of the pipeline system.

Revive Energy Chemicals DRAs are typically long-chain polymers that can significantly reduce turbulence in flowing fluids when injected into a pipeline. This reduction in turbulence allows the fluid to flow more smoothly, decreasing the energy required to pump the fluid through the pipeline.

Revive Energy Chemicals DRAs Portfolio

- Polyalphaolefin-based DRAs: Commonly used in crude oil pipelines.

- Polyacrylamide-based DRAs: Often used in water and refined product pipelines.

- Surfactant-based DRAs: Used for specific applications where traditional polymer-based DRAs are not effective.

Revive Energy Chemicals – Applications of DRAs

- Crude Oil Pipelines: To increase the flow rate and capacity of existing pipelines, reducing the need for additional infrastructure.

- Refined Product Pipelines: To enhance the transportation efficiency of gasoline, diesel, and other refined products.

- Water Injection Systems: Used in enhanced oil recovery processes to improve the efficiency of water injection.

- Multi-phase Pipelines: Applied in pipelines that transport a mixture of oil, gas, and water to improve flow dynamics.

Revive Energy Chemicals – Benefits of Using DRAs

- Increased Pipeline Throughput: By reducing drag, more fluid can be transported through the pipeline, enhancing capacity without additional infrastructure investment.

- Energy Savings: Lowering the frictional pressure drop reduces the power required for pumping, leading to significant energy savings.

- Cost Efficiency: Decreases operational costs by reducing energy consumption and delaying or eliminating the need for pipeline expansion projects.

- Reduced Wear and Tear: Smoother flow reduces mechanical stress on pipeline components, potentially extending the lifespan of the infrastructure.

- Enhanced Safety: Improved flow efficiency can lead to more stable operations and reduced risk of pipeline failures.

Drag Reducing Agents are crucial in optimizing the efficiency of fluid transportation in pipelines within the oil and gas industry. By mitigating turbulence, they enhance flow rates, reduce energy consumption, and offer economic and operational benefits. However, their application must be carefully managed to address potential limitations and ensure maximum effectiveness.

By choosing Revive Energy Chemicals’ DRAs, you can achieve maximum pressure drop, increased production, reduce operational costs through energy savings, and maintain smooth, efficient facility operations. Our expertise and customized approach ensure that you receive the best possible treatment solutions for your operations.